Some industrial park tenants, particularly small businesses, benefit from being located close to their main material suppliers. This proximity also provides an opportunity for establishing industrial synergy between tenant companies by using production waste from each other to produce new goods. For example, yarn production waste (bouffant) can be utilized in the production of non-woven material made from natural wool noils and polyester fiber.

Some industrial park tenants, particularly small businesses, benefit from being located close to their main material suppliers. This proximity also provides an opportunity for establishing industrial synergy between tenant companies by using production waste from each other to produce new goods. For example, yarn production waste (bouffant) can be utilized in the production of non-woven material made from natural wool noils and polyester fiber.

In 2023 the park management was provided by the project team with feasibility study of installation a roof rainwater collection system and the first demonstration project for 100m2 on the water tower roof was put into operation in 2024, and another one for 3,000m2 of the production facility roof now is under construction.

In 2023 the park management was provided by the project team with feasibility study of installation a roof rainwater collection system and the first demonstration project for 100m2 on the water tower roof was put into operation in 2024, and another one for 3,000m2 of the production facility roof now is under construction.

The management company during the period of the project established ability for direct communication via online application form on its website for its tenants and their staff to address potential claims and grievances efficiently.

The management company during the period of the project established ability for direct communication via online application form on its website for its tenants and their staff to address potential claims and grievances efficiently.

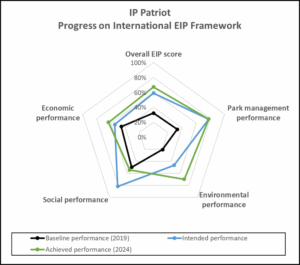

Despite being under continuous bombardment since the start of the war, IP PATRIOT successfully implemented several internal procedures, including a monitoring and risk plan, climate change adaptation measures, risk assessments,

EIP achievement tracking, water reuse initiatives, heat recovery, and a strategy to attract local SMEs. These efforts resulted in a 36% overall performance increase, with a 49% improvement in environmental performance and a 28% boost in economic performance. Despite its proximity to the frontline, the park was visited multiple times by subcontractors, focusing on the implementation of Resource Efficiency and Cleaner Production (RECP) and Industrial Symbiosis practices.

A new system for handling claims and grievances was also introduced to address negative experiences reported by tenants and workers. This newly established communication channel has significantly improved responsiveness to tenant concerns and enhanced overall satisfaction with park management services.